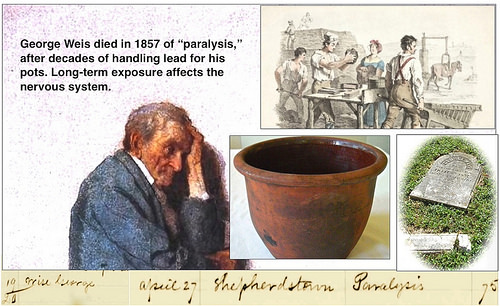

Check out these two shots mould china images:

CPR / My Neighbour to the West

Image by bill barber

From my set entitled “Our Home, Streetsville”

www.flickr.com/photos/21861018@N00/sets/72157600265395738/

In my collection entitled “Places”

www.flickr.com/photos/21861018@N00/collections/7215760074…

In my photostream

www.flickr.com/photos/21861018@N00/

I’ve always lived close to railway lines. When I was growing up in Orangeville, Ontario, I lived near the main station. Both the Canadian National Railway (CNR) and the Canadian Pacific Railway (CPR) passed through town. When my sister and I moved to a fifty acre farm in Dixie, Ontario (near Toronto) in 1960, the CPR bisected our land.

For the twenty-two years Karen and I have lived at our current address in Streetsville, Ontario, the CPR has been our neighbour across the back fence. People ask us, “Don’t the trains bother you?” We answer that we don’t even hear them.

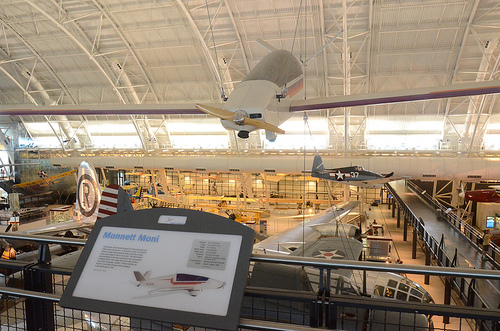

We sit on the deck and view a lot of interesting stuff go by. One day I watched a trainload of tanks pass. Didn’t know Canada had so many tanks. We also see intriguing graffiti on the sides of tankers and boxcars. And there are cars from all over the U.S. and Canada.

This is the first shot of the trains I have taken from the deck, but there will be more. It’s best to take such pictures after the leaves have dropped, since it’s hard to see the trains through the summer foliage.

Reproduced from Wikipedia, the free encyclopedia

en.wikipedia.org/wiki/Canadian_Pacific_Railway

The Canadian Pacific Railway (CPR; AAR reporting marks CP, CPAA, CPI), known as CP Rail between 1968 and 1996, is a Canadian Class I railway operated by Canadian Pacific Railway Limited. Its rail network stretches from Vancouver to Montreal, and also serves major cities in the United States such as Minneapolis, Chicago, and New York City. Its headquarters are in Calgary, Alberta.

The railway was originally built between eastern Canada and British Columbia between 1881 and 1885 (connecting with Ottawa Valley and Georgian Bay area lines built earlier), fulfilling a promise extended to British Columbia when it entered Confederation in 1871. It was Canada’s first transcontinental railway. Now primarily a freight railway, the CPR was for decades the only practical means of long distance passenger transport in most regions of Canada, and was instrumental in the settlement and development of Western Canada. The CP company became one of the largest and most powerful in Canada, a position it held as late as 1975.[1] Its primary passenger services were eliminated in 1986 after being assumed by VIA Rail Canada in 1978. A beaver was chosen as the railway’s logo because it is one of the national symbols of Canada and represents the hardworking character of the company. The object of both praise and condemnation for over 120 years, the CPR remains an indisputable icon of Canadian nationalism.

The Canadian Pacific Railway is a public company with over 15,000 employees and market capitalization of 7 billion USD in 2008.[2]

Canada’s very existence depended on the successful completion of the major civil engineering project, the creation of a transcontinental railway. Creation of the Canadian Pacific Railway was a task originally undertaken for a combination of reasons by the Conservative government of Prime Minister Sir John A. Macdonald. British Columbia had insisted upon a transport link to the east as a condition for joining the Confederation of Canada (initially requesting a wagon road). The government however, proposed to build a railway linking the Pacific province to the eastern provinces within ten years of July 20, 1871. Macdonald also saw it as essential to the creation of a unified Canadian nation that would stretch across the continent. Moreover, manufacturing interests in Quebec and Ontario desired access to sources of raw materials and markets in Canada’s west.

The first obstacle to its construction was economic. The logical route went through the American Midwest and the city of Chicago, Illinois. In addition to the obvious difficulty of building a railroad through the Canadian Rockies, an entirely Canadian route would require crossing 1,600 km (1,000 miles) of rugged terrain of the barren Canadian Shield and muskeg of Northern Ontario. To ensure this routing, the government offered huge incentives including vast grants of land in Western Canada.

In 1872, Sir John A. Macdonald and other high-ranking politicians, swayed by bribes in the so-called Pacific Scandal, granted federal contracts to Hugh Allan’s "Canada Pacific Railway Company" (which was unrelated to the current company) and to the Inter-Ocean Railway Company. Because of this scandal, the Conservative party was removed from office in 1873. The new Liberal prime minister, Alexander Mackenzie, began construction of segments of the railway as a public enterprise under the supervision of the Department of Public Works. The Thunder Bay branch linking Lake Superior to Winnipeg was commenced in 1875. Progress was discouragingly slow because of the lack of public money. With Sir John A. Macdonald’s return to power on October 16, 1878, a more aggressive construction policy was adopted. Macdonald confirmed that Port Moody would be the terminus of the transcontinental railway, and announced that the railway would follow the Fraser and Thompson rivers between Port Moody and Kamloops. In 1879, the federal government floated bonds in London and called for tenders to construct the 206 km (128 mile) section of the railway from Yale, British Columbia to Savona’s Ferry on Kamloops Lake. The contract was awarded to Andrew Onderdonk, whose men started work on May 15, 1880. After the completion of that section, Onderdonk received contracts to build between Yale and Port Moody, and between Savona’s Ferry and Eagle Pass.

On October 21, 1880, a new syndicate, unrelated to Hugh Allan’s, signed a contract with the Macdonald government. They agreed to build the railway in exchange for ,000,000 (approximately 5,000,000 in modern Canadian dollars) in credit from the Canadian government and a grant of 25,000,000 acres (100,000 km²) of land. The government transferred to the new company those sections of the railway it had constructed under government ownership. The government also defrayed surveying costs and exempted the railway from property taxes for 20 years. The Montreal-based syndicate officially comprised five men: George Stephen, James J. Hill, Duncan McIntyre, Richard B. Angus, and John Stewart Kennedy. Donald A. Smith and Norman Kittson were unofficial silent partners with a significant financial interest. On February 15, 1881, legislation confirming the contract received royal assent, and the Canadian Pacific Railway Company was formally incorporated the next day.

The CPR started its westward expansion from Bonfield, Ontario (previously called Callander Station) where the first spike was driven into a sunken railway tie. Bonfield, Ontario was inducted into Canadian Railway Hall of Fame in 2002 as the CPR First Spike location. That was the point where the Canada Central Railway extension ended. The CCR was owned by Duncan McIntyre who amalgamated it with the CPR and became one of the handful of officers of the newly formed CPR. The CCR started in Brockville and extended to Pembroke. It then followed a westward route along the Ottawa River passing through places like Cobden, Deux-Rivières, and eventually to Mattawa at the confluence of the Mattawa and Ottawa Rivers. It then proceeded cross-country towards its final destination Bonfield (previously called Callander Station).

Duncan McIntyre and his contractor James Worthington piloted the CCR expansion. Worthington continued on as the construction superintendent for the CPR past Bonfield. He remained with the CPR for about a year until he left the company. McIntyre was uncle to John Ferguson who staked out future North Bay after getting assurance from his uncle and Worthington that it would be the divisional and a location of some importance.

It was assumed that the railway would travel through the rich "Fertile Belt" of the North Saskatchewan River valley and cross the Rocky Mountains via the Yellowhead Pass, a route suggested by Sir Sandford Fleming based on a decade of work. However, the CPR quickly discarded this plan in favour of a more southerly route across the arid Palliser’s Triangle in Saskatchewan and through Kicking Horse Pass over the Field Hill. This route was more direct and closer to the American border, making it easier for the CPR to keep American railways from encroaching on the Canadian market. However, this route also had several disadvantages.

One consequence was that the CPR would need to find a route through the Selkirk Mountains, as at the time it was not known whether a route even existed. The job of finding a pass was assigned to a surveyor named Major Albert Bowman Rogers. The CPR promised him a cheque for ,000 and that the pass would be named in his honour. Rogers became obsessed with finding the pass that would immortalize his name. He found the pass on May 29, 1881, and true to its word, the CPR named the pass "Rogers Pass" and gave him the cheque. This however, he at first refused to cash, preferring to frame it, and saying he did not do it for the money. He later agreed to cash it with the promise of an engraved watch.

Another obstacle was that the proposed route crossed land controlled by the Blackfoot First Nation. This difficulty was overcome when a missionary priest, Albert Lacombe, persuaded the Blackfoot chief Crowfoot that construction of the railway was inevitable.

In return for his assent, Crowfoot was famously rewarded with a lifetime pass to ride the CPR. A more lasting consequence of the choice of route was that, unlike the one proposed by Fleming, the land surrounding the railway often proved too arid for successful agriculture. The CPR may have placed too much reliance on a report from naturalist John Macoun, who had crossed the prairies at a time of very high rainfall and had reported that the area was fertile.

The greatest disadvantage of the route was in Kicking Horse Pass. In the first 6 km (3.7 miles) west of the 1,625 metre (5,330 ft) high summit, the Kicking Horse River drops 350 metres (1,150 ft). The steep drop would force the cash-strapped CPR to build a 7 km (4.5 mile) long stretch of track with a very steep 4.5% gradient once it reached the pass in 1884. This was over four times the maximum gradient recommended for railways of this era, and even modern railways rarely exceed a 2% gradient. However, this route was far more direct than one through the Yellowhead Pass, and saved hours for both passengers and freight. This section of track was the CPR’s Big Hill. Safety switches were installed at several points, the speed limit for descending trains was set at 10 km per hour (6 mph), and special locomotives were ordered. Despite these measures, several serious runaways still occurred. CPR officials insisted that this was a temporary expediency, but this state of affairs would last for 25 years until the completion of the Spiral Tunnels in the early 20th century.

In 1881 construction progressed at a pace too slow for the railway’s officials, who in 1882 hired the renowned railway executive William Cornelius Van Horne, to oversee construction with the inducement of a generous salary and the intriguing challenge of handling such a difficult railway project. Van Horne stated that he would have 800 km (500 miles) of main line built in 1882. Floods delayed the start of the construction season, but over 672 km (417 miles) of main line, as well as various sidings and branch lines, were built that year. The Thunder Bay branch (west from Fort William) was completed in June 1882 by the Department of Railways and Canals and turned over to the company in May 1883, permitting all-Canadian lake and rail traffic from eastern Canada to Winnipeg for the first time in Canada’s history. By the end of 1883, the railway had reached the Rocky Mountains, just eight km (5 miles) east of Kicking Horse Pass. The construction seasons of 1884 and 1885 would be spent in the mountains of British Columbia and on the north shore of Lake Superior.

Many thousands of navvies worked on the railway. Many were European immigrants. In British Columbia, the CPR hired workers from China, nicknamed coolies. A navvy received between and .50 per day, but had to pay for his own food, clothing, transportation to the job site, mail, and medical care. After two and a half months of back-breaking labour, they could net as little as . Chinese navvies in British Columbia made only between .75 and .25 a day, not including expenses, leaving barely anything to send home. They did the most dangerous construction jobs, such as working with explosives. The families of the Chinese who were killed received no compensation, or even notification of loss of life. Many of the men who survived did not have enough money to return to their families in China. Many spent years in lonely, sad and often poor conditions. Yet the Chinese were hard working and played a key role in building the western stretch of the railway; even some boys as young as 12 years old served as tea-boys.

By 1883, railway construction was progressing rapidly, but the CPR was in danger of running out of funds. In response, on January 31, 1884, the government passed the Railway Relief Bill, providing a further ,500,000 in loans to the CPR. The bill received royal assent on March 6, 1884.

In March 1885, the North-West Rebellion broke out in the District of Saskatchewan. Van Horne, in Ottawa at the time, suggested to the government that the CPR could transport troops to Qu’Appelle, Assiniboia, in eleven days. Some sections of track were incomplete or had not been used before, but the trip to Winnipeg was made in nine days and the rebellion was quickly put down. Perhaps because the government was grateful for this service, they subsequently re-organized the CPR’s debt and provided a further ,000,000 loan. This money was desperately needed by the CPR. On November 7, 1885 the Last Spike was driven at Craigellachie, British Columbia, making good on the original promise. Four days earlier, the last spike of the Lake Superior section was driven in just west of Jackfish, Ontario. While the railway was completed four years after the original 1881 deadline, it was completed more than five years ahead of the new date of 1891 that Macdonald gave in 1881.

The successful construction of such a massive project, although troubled by delays and scandal, was considered an impressive feat of engineering and political will for a country with such a small population, limited capital, and difficult terrain. It was by far the longest railway ever constructed at the time. It had taken 12,000 men, 5,000 horses, and 300 dog-sled teams to build the railway.

Meanwhile, in Eastern Canada, the CPR had created a network of lines reaching from Quebec City to St. Thomas, Ontario by 1885, and had launched a fleet of Great Lakes ships to link its terminals. The CPR had effected purchases and long-term leases of several railways through an associated railway company, the Ontario and Quebec Railway (O&Q). The O&Q built a line between Perth, Ontario, and Toronto (completed on May 5, 1884) to connect these acquisitions. The CPR obtained a 999-year lease on the O&Q on January 4, 1884. Later, in 1895, it acquired a minority interest in the Toronto, Hamilton and Buffalo Railway, giving it a link to New York and the northeast US.

So many cost-cutting shortcuts were taken in constructing the railway that regular transcontinental service could not start for another seven months while work was done to improve the railway’s condition. However, had these shortcuts not been taken, it is conceivable that the CPR might have had to default financially, leaving the railway unfinished. The first transcontinental passenger train departed from Montreal’s Dalhousie Station, located at Berri Street and Notre Dame Street on June 28, 1886 at 8:00 p.m. and arrived at Port Moody on July 4, 1886 at noon. This train consisted of two baggage cars, a mail car, one second-class coach, two immigrant sleepers, two first-class coaches, two sleeping cars, and a diner.

By that time, however, the CPR had decided to move its western terminus from Port Moody to Gastown, which was renamed "Vancouver" later that year. The first official train destined for Vancouver arrived on May 23, 1887, although the line had already been in use for three months. The CPR quickly became profitable, and all loans from the Federal government were repaid years ahead of time.

In 1888, a branch line was opened between Sudbury and Sault Ste. Marie where the CPR connected with the American railway system and its own steamships. That same year, work was started on a line from London, Ontario to the American border at Windsor, Ontario. That line opened on June 12, 1890.

The CPR also leased the New Brunswick Railway for 999 years and built the International Railway of Maine, connecting Montreal with Saint John, New Brunswick in 1889. The connection with Saint John on the Atlantic coast made the CPR the first truly transcontinental railway company and permitted trans-Atlantic cargo and passenger services to continue year-round when sea ice in the Gulf of St. Lawrence closed the port of Montreal during the winter months.

By 1896, competition with the Great Northern Railway for traffic in southern British Columbia forced the CPR to construct a second line across the province, south of the original line. Van Horne, now president of the CPR, asked for government aid, and the government agreed to provide around .6 million to construct a railway from Lethbridge, Alberta through Crowsnest Pass to the south shore of Kootenay Lake, in exchange for the CPR agreeing to reduce freight rates in perpetuity for key commodities shipped in Western Canada. The controversial Crowsnest Pass Agreement effectively locked the eastbound rate on grain products and westbound rates on certain "settlers’ effects" at the 1897 level. Although temporarily suspended during World War I, it was not until 1983 that the "Crow Rate" was permanently replaced by the Western Grain Transportation Act which allowed for the gradual increase of grain shipping prices. The Crowsnest Pass line opened on June 18, 1899.

Practically speaking, the CPR had built a railway that operated mostly in the wilderness. The usefulness of the Prairies was questionable in the minds of many. The thinking prevailed that the Prairies had great potential. Under the initial contract with the Canadian Government to build the railway, the CPR was granted 25,000,000 acres (100,000 km²). Proving already to be a very resourceful organization, Canadian Pacific began an intense campaign to bring immigrants to Canada.

Canadian Pacific agents operated in many overseas locations. Immigrants were often sold a package that included passage on a CP ship, travel on a CP train, and land sold by the CP railway. Land was priced at .50 an acre and up. Immigrants paid very little for a seven-day journey to the West. They rode in Colonist cars that had sleeping facilities and a small kitchen at one end of the car. Children were not allowed off the train, lest they wander off and be left behind. The directors of the CPR knew that not only were they creating a nation, but also a long-term source of revenue for their company.

During the first decade of the twentieth century, the CPR continued to build more lines. In 1908 the CPR opened a line connecting Toronto with Sudbury. Previously, westbound traffic originating in southern Ontario took a circuitous route through eastern Ontario.

Several operational improvements were also made to the railway in western Canada. In 1909 the CPR completed two significant engineering accomplishments. The most significant was the replacement of the Big Hill, which had become a major bottleneck in the CPR’s main line, with the Spiral Tunnels, reducing the grade to 2.2% from 4.5%. The Spiral Tunnels opened in August. On November 3, 1909, the Lethbridge Viaduct over the Oldman River valley at Lethbridge, Alberta was opened. It is 1,624 metres (5,327 ft) long and, at its maximum, 96 metres (314 ft) high, making it the longest railway bridge in Canada. In 1916 the CPR replaced its line through Rogers Pass, which was prone to avalanches, with the Connaught Tunnel, an eight km (5 mile) long tunnel under Mount Macdonald that was, at the time of its opening, the longest railway tunnel in the Western Hemisphere.

The CPR acquired several smaller railways via long-term leases in 1912. On January 3, 1912, the CPR acquired the Dominion Atlantic Railway, a railway that ran in western Nova Scotia. This acquisition gave the CPR a connection to Halifax, a significant port on the Atlantic Ocean. The Dominion Atlantic was isolated from the rest of the CPR network and used the CNR to facilitate interchange; the DAR also operated ferry services across the Bay of Fundy for passengers and cargo (but not rail cars) from the port of Digby, Nova Scotia to the CPR at Saint John, New Brunswick. DAR steamships also provided connections for passengers and cargo between Yarmouth, Boston and New York.

On July 1, 1912, the CPR acquired the Esquimalt and Nanaimo Railway, a railway on Vancouver Island that connected to the CPR using a railcar ferry. The CPR also acquired the Quebec Central Railway on December 14, 1912.

During the late 19th century, the railway undertook an ambitious program of hotel construction, building the Château Frontenac in Quebec City, the Royal York Hotel in Toronto, the Banff Springs Hotel, and several other major Canadian landmarks. By then, the CPR had competition from three other transcontinental lines, all of them money-losers. In 1919, these lines were consolidated, along with the track of the old Intercolonial Railway and its spurs, into the government-owned Canadian National Railways.

When World War I broke out in 1914, the CPR devoted resources to the war effort, and managed to stay profitable while its competitors struggled to remain solvent. After the war, the Federal government created Canadian National Railways (CNR, later CN) out of several bankrupt railways that fell into government hands during and after the war. CNR would become the main competitor to the CPR in Canada.

The Great Depression, which lasted from 1929 until 1939, hit many companies heavily. While the CPR was affected, it was not affected to the extent of its rival CNR because it, unlike the CNR, was debt-free. The CPR scaled back on some of its passenger and freight services, and stopped issuing dividends to its shareholders after 1932.

One highlight of the 1930s, both for the railway and for Canada, was the visit of King George VI and Queen Elizabeth to Canada in 1939, the first time that the reigning monarch had visited the country. The CPR and the CNR shared the honours of pulling the royal train across the country, with the CPR undertaking the westbound journey from Quebec City to Vancouver.

Later that year, World War II began. As it had done in World War I, the CPR devoted much of its resources to the war effort. It retooled its Angus Shops in Montreal to produce Valentine tanks, and transported troops and resources across the country. As well, 22 of the CPR’s ships went to warfare, 12 of which were sunk.

After World War II, the transportation industry in Canada changed. Where railways had previously provided almost universal freight and passenger services, cars, trucks, and airplanes started to take traffic away from railways. This naturally helped the CPR’s air and trucking operations, and the railway’s freight operations continued to thrive hauling resource traffic and bulk commodities. However, passenger trains quickly became unprofitable.

During the 1950s, the railway introduced new innovations in passenger service, and in 1955 introduced The Canadian, a new luxury transcontinental train. However, starting in the 1960s the company started to pull out of passenger services, ending services on many of its branch lines. It also discontinued its transcontinental train The Dominion in 1966, and in 1970 unsuccessfully applied to discontinue The Canadian. For the next eight years, it continued to apply to discontinue the service, and service on The Canadian declined markedly. On October 29, 1978, CP Rail transferred its passenger services to VIA Rail, a new federal Crown corporation that is responsible for managing all intercity passenger service formerly handled by both CP Rail and CN. VIA eventually took almost all of its passenger trains, including The Canadian, off CP’s lines.

In 1968, as part of a corporate re-organization, each of the CPR’s major operations, including its rail operations, were organized as separate subsidiaries. The name of the railway was changed to CP Rail, and the parent company changed its name to Canadian Pacific Limited in 1971. Its express, telecommunications, hotel and real estate holdings were spun off, and ownership of all of the companies transferred to Canadian Pacific Investments. The company discarded its beaver logo, adopting the new Multimark logo that could be used for each of its operations.

In 1984 CP Rail commenced construction of the Mount Macdonald Tunnel to augment the Connaught Tunnel under the Selkirk Mountains. The first revenue train passed through the tunnel in 1988. At 14.7 km (9 miles), it is the longest tunnel in the Americas.

During the 1980s, the Soo Line, in which CP Rail still owned a controlling interest, underwent several changes. It acquired the Minneapolis, Northfield and Southern Railway in 1982. Then on February 21, 1985, the Soo Line obtained a controlling interest in the Milwaukee Road, merging it into its system on January 1, 1986. Also in 1980 Canadian Pacific bought out the controlling interests of the Toronto, Hamilton and Buffalo Railway (TH&B) from Conrail and molded it into the Canadian Pacific System, dissolving the TH&B’s name from the books in 1985. In 1987 most of CPR’s trackage in the Great Lakes region, including much of the original Soo Line, were spun off into a new railway, the Wisconsin Central, which was subsequently purchased by CN.

Influenced by the Canada-U.S. Free Trade Agreement of 1989 which liberalized trade between the two nations, the CPR’s expansion continued during the early 1990s: CP Rail gained full control of the Soo Line in 1990, and bought the Delaware and Hudson Railway in 1991. These two acquisitions gave CP Rail routes to the major American cities of Chicago (via the Soo Line) and New York City (via the D&H).

During the next few years CP Rail downsized its route, and several Canadian branch lines were either sold to short lines or abandoned. This included all of its lines east of Montreal, with the routes operating across Maine and New Brunswick to the port of Saint John (operating as the Canadian Atlantic Railway) being sold or abandoned, severing CPR’s transcontinental status (in Canada); the opening of the St. Lawrence Seaway in the late 1950s, coupled with subsidized icebreaking services, made Saint John surplus to CPR’s requirements. During the 1990s, both CP Rail and CN attempted unsuccessfully to buy out the eastern assets of the other, so as to permit further rationalization. As well, it closed divisional and regional offices, drastically reduced white collar staff, and consolidated its Canadian traffic control system in Calgary, Alberta.

Finally, in 1996, reflecting the increased importance of western traffic to the railway, CP Rail moved its head office to Calgary from Montreal and changed its name back to Canadian Pacific Railway. A new subsidiary company, the St. Lawrence and Hudson Railway, was created to operate its money-losing lines in eastern North America, covering Quebec, Southern and Eastern Ontario, trackage rights to Chicago, Illinois, as well as the Delaware and Hudson Railway in the U.S. Northeast. However, the new subsidiary, threatened with being sold off and free to innovate, quickly spun off losing track to short lines, instituted scheduled freight service, and produced an unexpected turn-around in profitability. After only four years, CPR revised its opinion and the StL&H formally re-amalgamated with its parent on January 1, 2001.

In 2001, the CPR’s parent company, Canadian Pacific Limited, spun off its five subsidiaries, including the CPR, into independent companies. Canadian Pacific Railway formally (but, not legally) shortened its name to Canadian Pacific in early 2007, dropping the word "railway" in order to reflect more operational flexibility. Shortly after the name revision, Canadian Pacific announced that it had committed to becoming a major sponsor and logistics provider to the 2010 Olympic Winter Games in Vancouver, British Columbia.

On September 4, 2007, CPR announced it was acquiring the Dakota, Minnesota and Eastern Railroad from its present owners, London-based Electra Private Equity.[3] The transaction is an "end-to-end" consolidation,[4][5] and will give CPR access to U.S. shippers of agricultural products, ethanol, and coal. CPR has stated its intention to use this purchase to gain access to the rich coal fields of Wyoming’s Powder River Basin. The purchase price is US.48 billion, and future payments of over US.0 billion contingent on commencement of construction on the smaller railroad’s Powder River extension and specified volumes of coal shipments from the Powder River basin.[4] The transaction was subject to approval of the U.S. Surface Transportation Board (STB), which was expected to take a year.[4] On October 4, 2007, CPR announced it has completed the financial transactions required for the acquisition, placing the DM&E and IC&E in a voting trust with Richard Hamlin appointed as the trustee. CPR planned to integrate the railroads’ operations once the STB approves the acquisition.[6] The merger was completed as of October 31, 2008.[7]

Post Processing;

Topaz: vibrance

PhotoShop Elements 5: crop, multiply, posterization, ink outlines, sandstone texture