Check out these injection moulding images:

Random International: Rain Room

Image by Jon’sTripBook

Olympus µ[mju:]-II

Kodak Ultramax 400

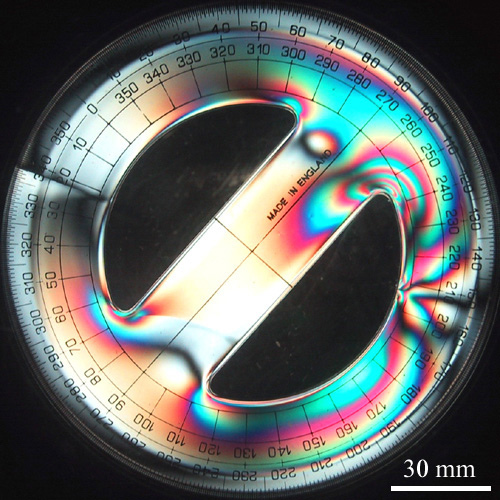

Injection-moulded protractor

Image by CORE-Materials

DoITPoMS, University of Cambridge

The colours in the image are the result of birefringence and relate to the residual strain in the polystyrene. The pattern of strain is indicative of the flow of material during the injection process and it highlights the injection point (at 152 degrees on the outer scale), and two ‘weld lines’ (at 338 and on the central bar) where two distinct flows of material meet. The weld line is a common point of failure because there is limited intermixing of the two fronts during the time allowed.

System

Polystyrene (PS)

Composition

Not specified

Reaction

Processing

Polystyrene was injected into a mould from a single point and has flowed round the component to meet at two noticeable ‘weld lines’

Applications

Polystyrene is hard and inexpensive and its use is very widespread. CD cases and clear plastic cups are common examples. Domestic appliance casings are also typically made from PS

Sample preparation

Technique

Cross-polarised light microscopy

Contributor

J A Curran

Organisation

Department of Materials Science and Metallurgy, University of Cambridge

View micrograph in DoITPoMS website

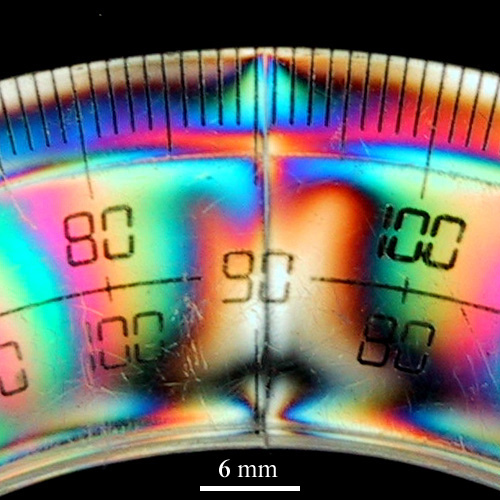

Injection-moulded protractor

Image by CORE-Materials

DoITPoMS, University of Cambridge

The colours in the image are the result of birefringence and relate to the residual strain in the polystyrene. The pattern of strain is indicative of the flow of material during the injection process and it highlights a ‘weld line’ where two distinct flows of material meet. The weld line is a common point of failure because there is limited intermixing of the two fronts during the time allowed.

System

Polystyrene (PS)

Composition

Not specified

Reaction

Processing

Polystyrene was injected into a mould from a single point and has flowed round the component to meet at a noticeable ‘weld line’

Applications

Polystyrene is hard and inexpensive and its use is very widespread. CD cases and clear plastic cups are common examples. Domestic appliance casings are also typically made from PS

Sample preparation

Technique

Cross-polarised light microscopy

Contributor

J A Curran

Organisation

Department of Materials Science and Metallurgy, University of Cambridge