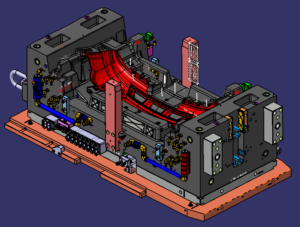

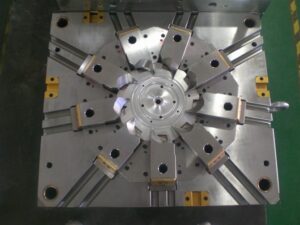

For china industrial injection mold manufacturers, their end goal of structural design , a center can be viewed as shallow when the tallness of the center is not exactly both the width and length of the center. Shallow centers, for example, for the bezel form, won’t be exposed to exorbitant pressure or redirection brought about by the use of the soften strain to the side dividers of the center. Thusly, shallow centers can be planned by the recently depicted investigation for form plates. Profound centers need further thought of pressure and avoidance as next examined.

The vertical redirection of centers because of pressure by the soften can be displayed as recently examined in Section 12.2.1, however with the compressive powers and cross-sectional regions proper for the center as demonstrated as a visual cue.

The underlying model of profound centers is additionally confounded since profound centers can twist because of the utilization of parallel powers from the liquefy pressure against their sides. Center twisting might be a critical issue when centers are thin and have a low firmness related with their cross-sectional region, es pecially when the centers are dug out to accommodate shape coolant. Investigation and plan of the center should guarantee that the potential center redirection isn’t inordinate and that the compressive anxieties around the border of the center are adequate, These two concerns are next tended to.

In the injection moulding services, it might create the impression that the cooling embed in the plan of Fig. 12.25 will completely uphold the center addition. While this presumption may demonstrate satisfactory, a more vigorous plan is given by expecting that the cooling embed offers no help. There are two explanations behind making this supposition. To start with, the external surfaces of the cooling addition may not firmly fit the inward surfaces of the center supplement. Any leeway or hole more noteworthy than the diversion of the center will totally forestall the cooling embed from supporting the center. Second, the cooling addition might be produced using an unexpected material in comparison to the center supplement, like aluminum. At that point, the cooling supplement probably won’t withstand the burdens im presented while sup porting the center addition.

The absolute diversion of the top surface of the center can be assessed by superimposing the pressure of the side dividers with the twisting of the top surface. While the compressive pressure dissemination in the side dividers of the center isn’t completely uniform, the normal pressure is around the applied power from the top isolated by the cross-sectional region of the side dividers.

China injection mold maker knows it well that bending from the edge of the top surface to the focal point of the center can be determined utilizing pillar or plate bowing conditions of Section 12.2.2 and added to the relocation because of pressure to appraise the absolute vertical redirection.

This article is from http://www.chinainjectionmold.com/